Machine vibration isolators are an essential tool for maximizing efficiency and productivity in various industries. By effectively reducing the transmission of vibration and shock from machinery, these isolators offer numerous benefits such as improved equipment lifespan, reduced maintenance costs, and enhanced worker safety. In this article, we will explore the advantages of using machine vibration isolators and how they can significantly improve the overall performance of industrial equipment.

Machine vibration isolators are essential for maximizing efficiency in various industrial applications. These isolators help to reduce the transmission of vibration and shock from machinery to its surrounding environment, preventing damage to the equipment and promoting a more stable work environment. By minimizing vibration, machine isolators can improve the performance and longevity of equipment, reduce maintenance costs, and enhance overall productivity. Additionally, they contribute to a safer and more comfortable work environment for operators. Overall, the benefits of incorporating machine vibration isolators are significant in optimizing efficiency and maintaining the integrity of equipment and facilities.

Machine vibration isolators play a crucial role in various industrial settings by mitigating the impact of vibration and shock on machinery. These isolators are designed to minimize the transfer of vibration to the surrounding environment, thereby preventing damage to equipment and ensuring a more stable work environment. By effectively reducing vibration, machine isolators can contribute to improved equipment performance, extended machinery lifespan, reduced maintenance costs, and enhanced overall productivity. Furthermore, they promote a safer and more comfortable workspace for operators. Overall, the integration of machine vibration isolators yields significant benefits in optimizing efficiency and safeguarding the integrity of equipment and facilities.

Understanding the Importance of Machine Vibration Isolators

Understanding the importance of machine vibration isolators is crucial for ensuring the smooth and efficient operation of industrial equipment. Vibration isolators are designed to reduce the transmission of vibrations from the machine to its surroundings, thereby preventing damage to the equipment and minimizing the impact on nearby structures and personnel. By effectively isolating the machine vibrations, these devices help to extend the lifespan of the equipment, improve its performance, and reduce maintenance costs. Furthermore, they contribute to creating a safe and comfortable working environment by minimizing noise and vibrations that can cause discomfort and fatigue. It is important to consider factors such as the type and size of the equipment, the level of vibration it generates, and the specific requirements of the application when selecting the right vibration isolator. Proper installation and maintenance of these isolators are also essential for maximizing their effectiveness and ensuring long-term reliability. In summary, machine vibration isolators play a crucial role in protecting equipment, improving performance, and creating a safe working environment. Understanding their importance is essential for achieving optimal results in industrial settings.

Types of Machine Vibration Isolators and Their Uses

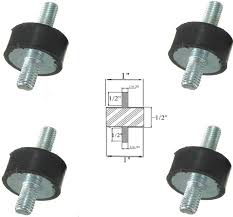

There are several types of machine vibration isolators, including spring isolators, elastomeric isolators, air isolators, and viscous dampers. Spring isolators use metal springs to absorb and isolate vibrations, while elastomeric isolators use rubber or similar materials to dampen vibrations. Air isolators use compressed air to isolate vibrations, and viscous dampers use hydraulic fluid to absorb and dissipate vibrations. These isolators are used in various industrial and commercial applications to reduce the transmission of vibrations from machinery to surrounding structures. They are commonly used in HVAC systems, power generation equipment, industrial machinery, and sensitive laboratory equipment. By effectively isolating vibrations, these isolators help to minimize noise, prevent structural damage, and improve the operational performance and longevity of the machinery.

The Benefits of Using Machine Vibration Isolators

Machine vibration isolators help to reduce the transmission of vibration and noise from industrial machinery into the surrounding environment. This can help to protect the machinery itself, as well as the structures and equipment nearby, from the damaging effects of excessive vibration. By absorbing and dissipating the energy generated by the machinery, vibration isolators can also improve the overall working conditions for personnel in the area, reducing the risk of injury and improving productivity. Additionally, they can help to extend the lifespan of the machinery by reducing wear and tear caused by vibration. Overall, using machine vibration isolators can lead to a safer, more efficient, and longer-lasting industrial operation.

How to Choose the Right Machine Vibration Isolator for Your Needs

When choosing the right machine vibration isolator for your needs, consider the weight and size of the machine, as well as the frequency and amplitude of the vibrations it produces. You will also need to determine the necessary level of isolation required for your specific application. Some common types of vibration isolators include rubber mounts, springs, and air mounts. It is important to carefully assess your needs and consult with a professional to ensure you select the most suitable isolator for your machine.

Common Problems and Solutions with Machine Vibration Isolators

Common problems with machine vibration isolators include improper installation, defective isolators, and inadequate maintenance. Improper installation can lead to the isolators not functioning as intended, while defective isolators can result in ineffective vibration isolation. Inadequate maintenance can also cause isolators to deteriorate over time, leading to increased machine vibration. Solutions to these problems can include ensuring proper installation of the isolators, regularly inspecting and maintaining the isolators, and replacing any defective isolators. It is also important to use high-quality isolators that are designed to withstand the specific vibration levels of the machine. Additionally, consulting with a vibration isolation expert can help in identifying and addressing any issues with machine vibration isolators.

Maximizing the Lifespan of Machine Vibration Isolators

Maximizing the lifespan of machine vibration isolators involves regular inspection and maintenance to ensure they are in good condition. This includes checking for wear and tear, adjusting and tightening any loose components, and replacing damaged or worn parts as needed. Proper installation and usage of the isolators is also crucial in extending their lifespan, as well as avoiding overloading or exceeding their weight capacity. Additionally, keeping the surrounding environment clean and free of debris can help prevent unnecessary strain and damage to the isolators. Regular testing and monitoring of the isolators' performance can also help identify any issues early on and prevent further damage.

Improving Machine Performance with Vibration Isolation Technology

Improving Machine Performance with Vibration Isolation Technology involves reducing the transmission of vibration and shock between a machine and its surroundings. This can be achieved through the use of materials such as rubber mounts, springs, or air mounts to isolate the machine from its supporting structure. By reducing the impact of external vibrations, the machine can operate more efficiently, with less wear and tear, and produce more consistent results. Vibration isolation technology is commonly used in manufacturing, automotive, aerospace, and other industries where precise and reliable machine performance is critical.

The Future of Machine Vibration Isolators: Innovations and Advancements

The future of machine vibration isolators is driven by innovations and advancements in material science, design, and technology. New materials such as advanced polymers and composites are being developed to provide better isolation properties while also being more durable and cost-effective. Advancements in design are leading to more efficient and effective vibration isolators that can be tailored to specific applications and environments. This includes the use of advanced modeling and simulation techniques to optimize isolator performance. Technological advancements are also playing a key role in the future of machine vibration isolators. This includes the integration of smart sensors and control systems that can actively monitor and adjust isolator performance in real-time to provide optimal vibration isolation. Overall, the future of machine vibration isolators is focused on providing better performance, durability, and adaptability to meet the evolving needs of modern machinery and equipment. These innovations and advancements are helping to drive improved efficiency, reliability, and safety in a wide range of industrial and commercial applications.

In conclusion, machine vibration isolators offer numerous benefits in maximizing efficiency and productivity in various industries. By effectively reducing vibrations and minimizing the impact of machinery on surrounding equipment and structures, these isolators help extend the lifespan of machinery, improve worker safety, and decrease maintenance costs. Implementing machine vibration isolators is essential for achieving an optimal work environment and ensuring the smooth operation of industrial equipment.

See also

https://www.lanpdt.com/vibration-isolation/ https://www.heliwigcarbon.com/products/vibration-isolators/